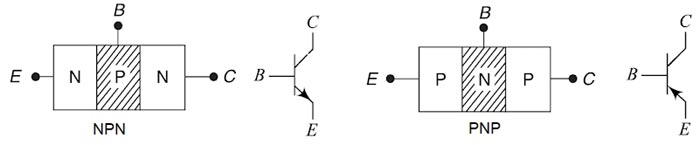

A Bipolar Junction Transistor (BJT) is a three-layer, two junction semiconductor device consisting of either two N-type and one P-type layer of material (NPN transistor) or two P-type and one N-type layer of material (PNP transistor). A transistor can be visualized as two back-to-back connected diodes; by placing two PN junctions together, we can create a bipolar transistor with the three terminals – emitter, base, and collector. The term bipolar is to justify the fact that holes and electrons participate in the injection process into the oppositely polarised material. If only one carrier is employed (electron or hole), it is considered a unipolar device. For proper working of the transistor, the two junctions of the transistor should be properly biased, the base-emitter (J1) junction should be forward biased and the base-collector (J2) junction should be reverse biased. In a PNP transistor, the majority charge carriers are holes and germanium is favored for these devices. In an NPN transistor, the majority charge carriers are electrons and silicon is best for NPN transistors. The thin and lightly doped middle layer is known as the base (B) and the two outer regions are known as the emitter (E) and the collector (C).

Under the proper operating conditions, the emitter region emits or injects majority charge carriers into the base region and because the base is very thin, most of these electrons will ultimately reach the collector. The emitter is highly doped to reduce resistance and emit more majority charge carriers. The collector is lightly doped to reduce the junction capacitance of the collector-base junction. The schematics and the circuit symbols for bipolar transistors are shown in Fig. The arrows on the schematic symbols indicate the direction of emitter-current flow. The collector is usually at a higher voltage than the emitter and for proper operation, the base-emitter junction is forward biased while the collector-base junction is reverse biased.